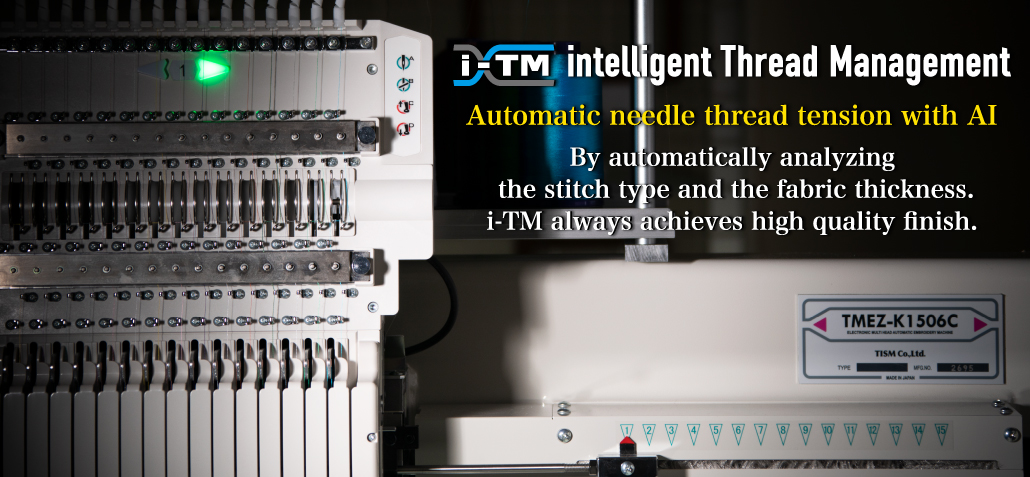

TMEZ-KC

THE WORLD’S FIRST . An innovative embroidery machine without manual thread tension adjustment.

Automated optimization of embroidery quality by i-TM

The industry’s first technology “i-TM” (automatic upper thread tension adjustment) is now available on the multi-head cylinder-type machine that can be applied to ready-made products.

Automated optimization of embroidery quality by i-TM

The industry’s first technology “i-TM” (automatic upper thread tension adjustment) is now available on the multi-head cylinder-type machine that can be applied to ready-made products.

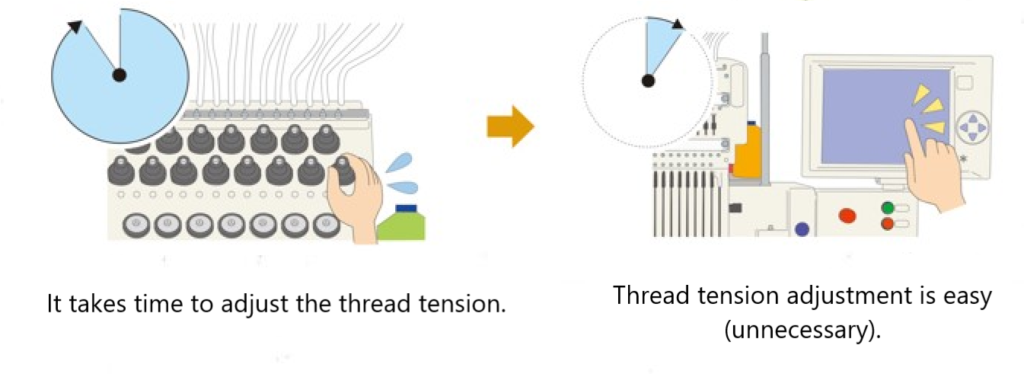

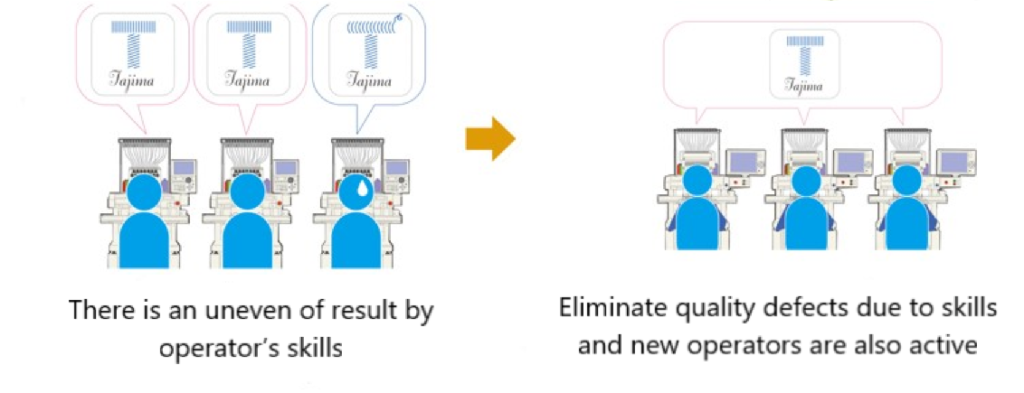

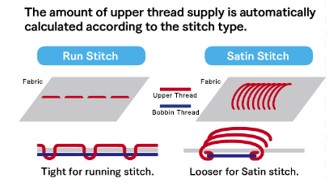

It is about i-TM that provides optimal tension adjustment.

Reduction of adjustment time

Uneven of result by operator

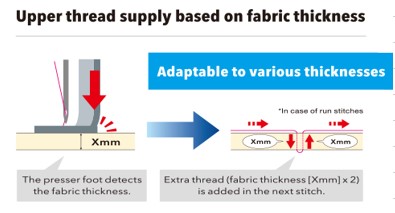

Beautiful finish even on thick materials and leather

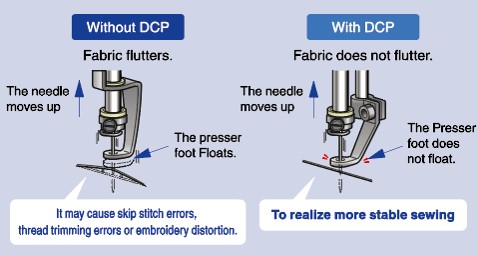

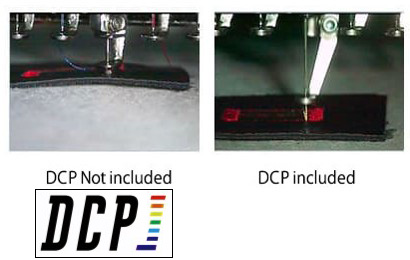

The digitally controlled presser foot reduces fluttering of the fabric and gives precise and beautiful embroidery finish.

It is ideal for locations and materials that can easily flutter, such as sewing seams, leather, and thick and/or elastic fabrics.

※DCP stands for Digitally Controlled Presser foot.

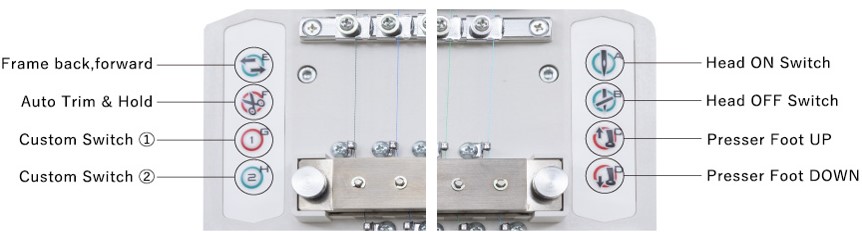

Direct command switches

Reinforcement of fundamental performance

Reinforced tubular frame arm

The newly-designed arms have been made 3 times more rigid than the conventional type, easing the support of heavy items like jackets.

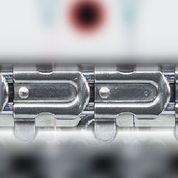

Reinforced upper thread lock

The upper thread lock has been reinforced so it can hold the thread on suspended heads more firmly to avoid thread cast-off and to reduce the occurrence of stitching errors at the start of embroidery.

Upgraded main shaft motor

The improved torque of the main shaft has led to higher penetration, allowing stable embroidery even on thick materials like leather.

Cap embroidery enhanced in pursuit of higher productivity

Reinforcement of the cap frame support structure has contributed to stabilization of the embroidery finish, by dramatically increasing the maximum rotation speed up to 1,000 rpm.

Others

New auto thread trimming device

The picker has been eliminated for easier under thread exchange.The whole trimming mechanism has also been redesigned for stable trimming under various conditions.

12.1-inch TFT touch panel

The large monitor allows intuitive operation of the panel.

| MODEL | Needles | Multicolor | Head interval | Embroidery space(D×W) | A (mm) | B (mm) | C (mm) |

|---|---|---|---|---|---|---|---|

| K0902C | 9 | 2 | 500 | 450 × 500 | 2,260 | 1,355 | 1,730 |

| K0904C | 9 | 4 | 360 | 450 × 360 | 2,560 | 1,355 | 1,730 |

| K0904C | 9 | 4 | 500 | 450×500 | 3,260 | 1,355 | 1,740 |

| K0906C | 9 | 6 | 360 | 450 × 360 | 3,280 | 1,355 | 1,740 |

| K0906C | 9 | 6 | 500 | 450 × 500 | 4,260 | 1,355 | 1,740 |

| K0908C | 9 | 8 | 360 | 450 × 360 | 4,000 | 1,355 | 1,740 |

| K0908C | 9 | 8 | 500 | 450 × 500 | 5,260 | 1,355 | 1,740 |

| Option | : Multi Cording Device, Sequin Device IV |

| Revolution | : Max. 1,100 rpm |

| Power consumption | : 420 w (720VA) |

| Power Supply | : 1-PH 220V 50Hz |